Blockchain traceability industry research report

Overview

In human history, we have never had such a large-scale trade activity. Today, we live in a global trading network with complex supply chains that can start from one country and connect to more than a dozen countries. Although throughout history, food production and supply have generally been dominated by the country. But today, an estimated 23% of human food comes from international trade. Timber product supply chains are equally complex and can even bypass the legal systems of some countries. These complications provide a breeding ground for illegal acts. It is estimated that 1.5% of global GDP ($ 870 billion) is provided by illegal, unreported or unregulated goods. To ensure product safety and integrity, we must have a legal and traceable system from the supply chain end to the client.

Report

The need for traceability

According to data released by the General Administration of Customs on January 14, China's total foreign trade import and export value in 2018 reached 30.51 trillion yuan, which was 2.7 trillion yuan more than the historical high in 2017, an increase of 9.7% year-on-year, and the scale hit a record high. As the world's largest exporter, China will inevitably encounter importing countries' testing of China's export commodities. At this time, traceability technology can solve the problem of basic trust, thereby improving the overall efficiency of the supply chain.

- A solution to realize small and micro payments of digital currency

- 2019: "Year of the Blockchain" in Washington, Silicon Valley and Beijing

- SIBC Lands in Qiantang New District, Hangzhou, Builds Asian Blockchain Project Bridgehead

At the same time, government regulations and large retailers are promoting the use of product traceability technology. The European Union has required the establishment of a traceability system since January 2005. Businesses must be able to identify all food and food suppliers and all businesses that provide food or feed to them. Since the directive requires that all information must be provided to inspection agencies on demand, the need to store information in a systematic way for easy access is highlighted. The Bioterrorism Act, enacted in the United States in December 2005, requires that records be kept to identify previous direct sources and subsequent direct recipients. Traceability systems vary depending on the size of the country, the complexity of the supply chain, and other factors.

Supply chain traceability process

Source: Standard Consensus

Challenges of current traceability technologies

Mistrust in supply chain coordination

Complex global supply chains (such as those in this report) involve many independent players, including producers, brokers, transporters, processors, wholesalers, retailers, and consumers. They may not trust each other, and this distrust will greatly limit the efficiency of the whole chain collaboration. For example, these participants may be reluctant to share data.

Heavy and costly data reconciliation process

As the business expands to multiple countries and regions, traceability requirements may be difficult to meet to track inventory and manage numerous data and local laws and regulations. Often, supply chain management leads to a lot of duplicate data and a huge effort to track and coordinate data for individual products from beginning to end.

Many of these parties end up with identical copies of documents (such as certificates, shipping orders, bills of lading, pallets, goods, etc.) and data out of sync, making it difficult to identify the original version or decipher its accuracy. In many cases, these reconciliation processes are still based on manual and paper carriers, and errors and data duplication will increase reconciliation costs and increase the complexity of source chain tracing. For example, beef is a highly processed commodity, and its product identification needs to be changed through the entire storage process and production and marketing chain. The need for reliable data between the parties is highlighted by this complexity.

Lack of product traceability

A 2011 report by the American Food Manufacturers Association showed that most companies that experienced first-level recalls have financial impacts of more than $ 10 million. Nearly a quarter of companies reported a financial impact of a single recall of more than $ 30 million.

The main challenge of traceability is the ambiguity of product information-this is caused by product characteristics that are difficult to trace and uncertain. Poorly maintained records that complicate the supply chain and lag in identification may be the reason for this problem. When more than one product is stored, transported, or when semi-finished or finished products are made from raw materials, traceability becomes extremely difficult. Traceability issues also arise when a product changes identifiers or ownership, repackages, or changes in naming and labeling methods.

Commodity traceability status

At present, the global supply chain industry is committed to the pursuit of product traceability. Consumer demand and the introduction of government regulations on food safety and legality, such as the Lacey Act or Dodd Frank Act, are fueling this trend. A 2014 report from Allied Market Research predicts that the global food traceability technology market will grow at an annual rate of 8.7% and its size will reach $ 14.1 billion by 2020.

For a long time, the supply chain traceability industry has lacked effective, relatively inexpensive, and easy-to-use technologies. Today, the traceability technology has undergone considerable changes, and different types of technical solutions have emerged in an endless stream. However, it is still a challenge to find a technical solution with deep involvement and full chain traceability. It is still unknown whether the current technology can provide full chain traceability.

The most basic way to identify and track products is through paper documents. But one obvious disadvantage is that documents are easily forged. Misidentification and false publicity of species and origins have always been a problem in all supply chains. To give a very simple example, there was a time when certain Chinese companies used Dongting Lake hairy crabs to impersonate the more expensive Yangcheng Lake hairy crabs.

Some identification and traceability tools are listed in the following table:

Among them, the most important traceability technologies are the following three:

RFID radio frequency traceability technology

RFID radio frequency technology is to put a chip with a label on the product packaging, the product can automatically collect and read relevant information when entering and leaving the warehouse and transportation, and record the flow of the product on the chip. As the cost of this technology decreases, RFID is increasingly used to improve product traceability. Some retailers and government agencies use RFID smart tags to track product movements throughout the supply chain. This process is achieved by placing a smart label (a very flat transponder configured below a conventional print-encoded label) on the product, and the label relies on radio frequency communication between the smart label and the portable storage device and host to exchange data. RFID tags can be encoded with a variety of information and then collected with an RFID reader. RFID does not require human intervention. It can be passively used to track the movement of products in closed systems (such as warehouses) without scanning barcodes or tags, and can read multiple RFID smart tags simultaneously.

Two-dimensional code traceability technology

The QR code is a label. It is equivalent to add an ID card to the product. After the system enters the QR code, you can query the source of the product. Consumers only need to take a QR code through a mobile phone with a camera to query the relevant information of the product, and the query records will be kept in the system. Once the product needs to be recalled, they can directly send text messages to consumers to achieve accurate recall. This system can also help companies to digitally manage their own products, to achieve channel management, sales management, inventory management, to prevent channeling, and to distinguish between true and false.

Barcode traceability technology

Another way is to use the barcode to add product batch information (such as production date, production time, batch number, etc.). Production enterprises using this method basically do not increase production costs. From the market point of view, all products sold by the supermarkets need to register the product barcode. This bar code is the only one in the world, through which you can conduct trade transactions on a global scale. As long as you scan the bar code, you can get some basic information about the product, including information about the manufacturing company and so on. The barcode is the unique identification of the product and can be understood as the identity card of a product. Therefore, using a bar code as a means of tracing, or a tool for tracing and searching is very convenient and easy to implement.

Source: digitimes

Blockchain traceability technology

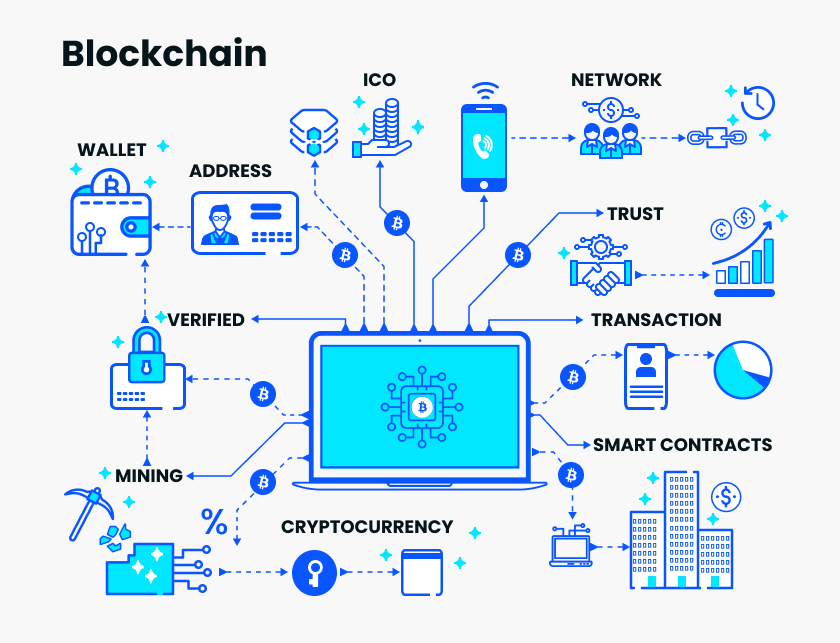

This technology records and stores every transaction on the entire network through a block structure with encrypted links. This structure is replicated among network participants, and each block has a hash, which is the output of an algorithm that converts the contents of the block into a random mixture of letters and numbers. Relevant participants or organizations participating in the distributed network can act as "nodes" to participate in consensus. This process keeps each blockchain node in sync, it can also handle the addition of new blocks, and it can use different mechanisms To build consensus, these mechanisms require trade-offs between confidentiality, throughput, and security, and depend on actual situations and specific cases.

Three architectures of blockchain traceability technology

Public blockchain

Public blockchains use complex algorithms to reach consensus among network participants, but in many cases it may not be suitable for companies because their privacy protection is limited compared to private blockchains. In the traceability process of public blockchains, the quality of products is controlled by different nodes. Relevant participants in the supply chain record all product information in public channels, and all nodes confirm the information through a consensus mechanism and receive rewards in digital currency.

Alliance Blockchain

The alliance blockchain is a blockchain with several institutions or organizations jointly participating in the management. Each participating institution or organization runs one or more nodes in it. The data in it is only allowed to be read by different institutions in the system Write and send transactions, and collectively record transaction data. Through the cross-validation of participating institutions, the traceability, query, and falsification of commodity information can be realized.

Private blockchain

Private blockchains designate network participants by using an access control layer, and typically use high-throughput consensus mechanisms. So far, there is no application of private blockchain in the traceability system.

Depending on the type of blockchain platform used, the blockchain can be designed to provide different levels of access to data on the blockchain. This means that it can both increase the transparency of the data and, if necessary, maintain privacy. For example, blockchain can enable patients to control their own health data and choose who can access their health data.

Source: Bitcoin

The value of blockchain in the traceability industry

Although relatively new, blockchain has already made its mark in the traceability industry. Blockchain technology has the following advantages, and these advantages are valuable to each participant in the supply chain.

Transparency and auditability

The lack of consistent data validation and data sharing capabilities makes it difficult to share information throughout the supply chain. The blockchain can just increase transparency and simplify the process of sharing information. Because each participant can upload information and data about their products, this transparency also helps increase trust. The blockchain can also display near real-time updates on products. Anyone in the supply chain can view the location, manufacturer, manufacturing method and expected delivery time of the product through a common platform. Through a significantly simplified process, participants are able to achieve shorter delivery times, reducing redundancy and delays.

A blockchain-based information sharing solution can provide public verification of whether contracts and agreements have been adhered to and properly documented. Because each transaction is recorded in sequence, the blockchain provides a permanent audit trail that can verify the authenticity of the product and track it through the chain of custody of production and sales. Many of the complexity, high cost, and inefficiency of current processes can be reduced by enabling blockchain systems, which effectively reduces data duplication.

Product traceability

Supply chain participants are increasingly investing in food safety traceability software, enabling them to see where a product is and where it came from in the supply chain.

The traceability platform developed using blockchain technology can also meet the US Food and Drug Administration (FDA) compliance requirements in the event of a recall, allowing them to access data and detect problems faster, including batch numbers, production and expiration And the product order number. Here, blockchain can become an important game changer by enabling interoperability between these various traceability solutions without having to change applications or use a single solution for all entities in the supply chain . This is very valuable when there are multiple entities in the supply chain that do not need or want to integrate directly with each other or are affected by the technical or business decisions of another entity. Although the China Food and Drug Administration currently does not have such specific traceability requirements as the United States, such real needs still exist.

Blockchain can enable data sharing without changing the systems owned by each entity, enabling greater product traceability across multiple partners, locations, and facilities. Each participant can view the same data throughout the life of the product.

Streamline operations and procurement process automation

Because the current supply chain is primarily based on paper records and manual processes, tracking products, especially during recalls and reconciliations and transaction reconciliations, can be expensive and time consuming. With the help of blockchain, critical information is stored and made available to users who need it almost in real time. Applications located on the blockchain platform can move data to the blockchain through manual input or automated processes or technologies (for example, through automatic sensors that measure the temperature in a transport truck).

Smart contracts are based on a blockchain system and can automatically execute the rules and process steps agreed by participants, thereby simplifying, validating and enforcing the terms of agreements between counterparties without manual intervention. In traditional database terminology, a smart contract is like a "stored procedure", but in this case it represents an agreement between multiple entities, such as service payment or shipment authorization. Because the blockchain is distributed and extensible, it can build and support global partnerships and simplify the communication process.

Blockchain traceability industry application case-food supply chain

Technology Overview

Source: Standard Consensus

Source: Standard Consensus

We found that the blockchain solution is mainly divided into six main parts:

User interface

User interfaces are designed for different users and are divided into three categories:

End user-consumer

These users use their mobile devices and dedicated applications to solve the problem. First, the terminal application should be a read-only program, so no login is required. Consumers can then access information related to that particular product by scanning a barcode, RFID sensor or QR code. Depending on the choice of solution, consumers can access all steps in the supply chain or just the production site and food instructions.

Professional users-wholesalers, retailers, shipping companies, farmers and processing and packaging companies

Each of these can have an interface through a mobile device or desktop or integrated into an ERP system. They will understand the upper and lower sides of the supply chain, as well as the source of the food and the various specifications, and in some cases, they can get more information than consumers need.

Smart Contract-Software Administrator

These users will manage contracts for other users. If processes or contracts must change, they will be managed through this interface. Managers can be trusted public institutions, companies, groups of companies. Generally speaking, the contract code should be open source so that all participants can see any changes, and if there is a setting to govern this, participants can also question.

File storage

The information added to the blockchain is usually limited. The content in the blockchain will not contain all the information, but rather the contract verification, hashing and identification of the person who added this information. For example, if a farmer took a photo of a crop and added it to the blockchain, the photo could be:

- Uploading to the blockchain is completely transparent to the nodes in the blockchain, but this requires the blockchain to store a large amount of information (public chain).

- Uploaded to a separate database, but accessed by the blockchain. Everyone who interacts with the blockchain can restrict access or open access (private chain).

- Stored in a database owned or controlled by the person or organization that uploaded the photo, but not accessible via the blockchain. Only the creator of the file / photo can decide who to share the data with (chain of alliances).

Blockchain

In public blockchains such as Bitcoin and Ethereum, anyone can become a node and keep a copy of the general ledger. They can be nodes that verify and accept transactions and information that will be stored in the block, or they can simply keep a record of others' commitments to the blockchain. In practice, those who want to be nodes that verify transactions need high processing power to have the opportunity to be part of the system. Due to transaction costs, public chain architecture cannot be a reasonable alternative in traceability projects. Even if the transaction cost of Ethereum is greatly reduced, the transaction capacity is also limited, and the transaction cost will become a limitation for price-sensitive industries such as the food industry. At present, licensing is the key to the development of the Internet of Things blockchain.

Smart contract engine

The application or contract engine is a key element of the solution. Ethereum is the most famous application blockchain solution. In Ethereum, contracts are called distributed applications. The application is run on the blockchain by all nodes and they are distributed. In some cases, the contract does not run on the blockchain. They are confirmed in the blockchain, and it can be said that their verification is embedded in the blockchain, but the entire application is not run by the blockchain network.

Authentication and authorization

Participants who have to authorize different steps in the process must be identified-this is one of the main challenges encountered by blockchain solutions. For Bitcoin, having the right private key is enough to authorize the use of the relevant Bitcoin. The problem is that key storage is crucial: most consumers cannot securely store their private keys for long periods of time, and if the private key is lost or stolen, all bitcoins will be lost. In most cases, consumers trust the custodian and entrust them to take care of the keys. As far as food is concerned, security is not so critical. IBM may be adequate in many cases. But if the system is to be global, a broader governance system is needed. Small IT companies even need some external trust provider, public agency or large company in their local implementation to use product identification solutions.

Blockchain may be the preferred technology for creating product identification solutions in the future, and it may be quite simple to increase the security level of product identification solutions through blockchain. For example, if a public agency or individual wants higher security in the form of a copy of a driver's license, a contract to make a copy and add it to the blockchain is very easy to do. It is not difficult to adjust the product certification solution through the blockchain to ensure flexibility.

Food item registrant

For food, there are many organizations and agencies that may be interested in food labels using their certificates. Authorities can assign specific quotas to certain foods. Public agencies can assign a code to track farmers / fishermen / food producers etc. and their production. The quantity produced or sold by farmers such as crops / fish will get this code in the blockchain. In these cases, blockchain provides a solution for participants to track the use of specific features or certificates related to specific food identities. When data is uploaded to the blockchain, organizations such as MSC (Marine Stewardship Council) can track the number of MSC-certified fish in the supply chain. If there are too many MSC-certified fish on the market, the MSC can check who is overusing its certification, so it can be guaranteed that only fish with the MSC label can reach consumers. The credibility of a certification authority depends on the correct use of data labels by verified farmers or producers. Therefore, the ability to track who uses the label and prevent it from being reused is critical. For example, if a producer sells organic products exclusively, but produces one-third according to these standards, the producer is given a limited code quota. If the producer tries to use the same code multiple times, he will be concerned and suspected by the system, and even be punished accordingly.

Conclusion

The first part of this article briefly outlines the necessity of blockchain source tracing, industry status, mainstream source tracing technology, and the value of blockchain technology. The second part of this article will start from the perspective of the food industry supply chain and elaborate on specific cases of blockchain technology from design to application.

We will continue to update Blocking; if you have any questions or suggestions, please contact us!

Was this article helpful?

93 out of 132 found this helpful

Related articles

- Filecoin test network is about to go live, these changes need attention

- Global Blockchain Investment Statistics in November: U.S. investment agencies are the most active, occupying "half of the country"

- Nine reasons why the Lightning Network will break out in 2020

- US SEC Chairman: Blockchain technology development helps promote capital formation and provides investment opportunities for investors

- Analysis | 3 key indicators to measure the performance of the blockchain network

- Interpreting DSR: Is DAI one step closer to real money?

- A few pictures take you to understand the new Nike patent "CrpytoKicks"